- Tel: +44 (0)1384 263279

- Fax: +44 (0)1384 480609

- sales@deancast.com

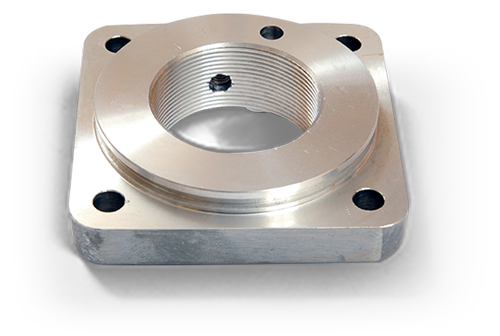

Aluminium Gravity Die Casting Alloy LM25

This alloy conforms to BS 1490:1988 LM25. Castings are standardised in the cast (M) condition, the precipitation treated (TE) condition, the solution treated and stabilised (TB7) condition and the fully heat treated (TF) condition.

Mechanical Properties

| LM25-M | LM25-TE | LM25-TB7 | LM25-TF | |||||

|---|---|---|---|---|---|---|---|---|

| Sand | Gravity | Sand | Gravity | Sand | Gravity | Sand | Gravity | |

| 0.2% Proof Stress (N/mm2) | 80-100 | 80-100 | 120-150 | 130-200 | 80-110 | 90-110 | 200-250 | 220-260 |

| Tensile Strength (N/mm2) | 130-150 | 160-200 | 150-180 | 190-250 | 160 | 230 | 230-280 | 280-320 |

| Elongation (%) | 2 | 3 | 1 | 2 | 2.5 | 5 | - | 2 |

| Impact resistance Izod (Nm) | - | - | - | - | - | - | - | - |

| Brinell Hardness | 55-65 | 55-65 | 70-75 | 75-95 | 65-75 | 65-75 | 90-110 | 90-110 |

| Modulus of Elasticity (x103 N/mm2) | 71 | 71 | 71 | 71 | 71 | 71 | 71 | 71 |

| Shear Strength (N/mm2) | - | - | 140 | - | - | - | 180 | 250 |

Physical Properties

| Value | |

|---|---|

| Coefficient of Thermal Expansion (per C @ 20-100 C) | 0.000022 |

| Thermal conductivity (cal/cm2/cm/ C @ 25 C) | 0.36 |

| Electrical conductivity (% copper standard @ 20 C) | 39 |

| Density (g/cm3) | 2.68 |

| Freezing range (C) approx. | 615-550 |

Strength at elevated temperatures

The tensile properties of LM25 alloy at elevated temperatures are influenced by the condition (heat treatment) of the castings and the duration at the elevated temperature. On short term testing e.g. 30 minutes at temperature, the properties fall only slowly and uniformly up to about 200 deg C, at which temperature the strength of LM25-TF is reduced by about 20%. Very prolonged heating, e.g. 10,000 hours, results in a sharp loss of strength at about 135 deg c. At 200 deg C the strength of LM25-TF is less than half of that at room temperature. There is therefore no advantage to be gained by heat treatment, if the component is to be used at temperatures above about 130 deg C, for extended periods of time.

Machinability

The heat-treated alloy has fairly good machining properties, but tools should preferably be of high speed steel and must be kept sharp. A moderately high rate of tool wear may be expected. Liberal cutting lubricant should be employed.

Corrosion Resistance

Resistance to corrosive attack by sea water and marine atmospheres is high with this alloy.

Anodising

A protective anodic film can be obtained by either the sulphuric or chromic acid process, but the grey opaque character of coatings of normal thickness precludes their colouring in light shades for decorative purposes.

Heat Treatment

There are three common heat treated conditions for LM25:TE (precipitation treated), TB7 (solution treated and stabilised, and TF (fully heat treated).

Application and General notes

LM25 is mainly used where good mechanical properties are required in castings of shape or dimensions requiring an alloy of excellent castability in order to achieve the desired standard of soundness. The alloy is also used where resistance to corrosion is an important consideration, particularly where high strength is also required. It has good weldability.

Consequently, LM25 finds application in the food, chemical, marine, electrical and many other industries and, above all, in road transport vehicles where it is used for wheels, cylinder blocks and heads, and other engine and body castings. Its potential uses are increased by its availability in four conditions of heat treatment in both sand and gravity die castings. It is, in practice, the general purpose high strength casting alloy, whose range of uses is increased by its availability in the as-cast and partially heat-treated condition as well. It is used in nuclear energy installations and for aircraft pump parts. LM25 may be superior for castings, particularly in gravity dies, which are difficult to make to the required standard of soundness. It offers better machinability and mechanical properties than LM6.