- Tel: +44 (0)1384 263279

- Fax: +44 (0)1384 480609

- sales@deancast.com

Gravity Die Casting

Deancast offer a wide range of services including production of premium quality, production-quantity aluminium gravity die-cast and or CNC machined. Offering all processes on site also allows us to shorten lead times and reduce costs.

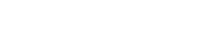

Precision Aluminium Castings

Our flexible range of gravity die casting facilities allows production of small batch and high volume parts; using conventional and semi-automatic gravity die casting techniques.

Dimensional Accuracy and Integrity

All our dies are meticulously maintained in our in-house tool room, to ensure repeatable premium quality parts. Our Gravity Die Castings are checked hourly to ensure dimensional accuracy and integrity and furnaces are temperature controlled to ensure consistent metal flow and solidification properties.

Typical Materials

Select any of the materials above to read more about their properties and typical uses. We cast many more aluminium grades, please call us to discuss your specific requirements.

Contact us for more information...

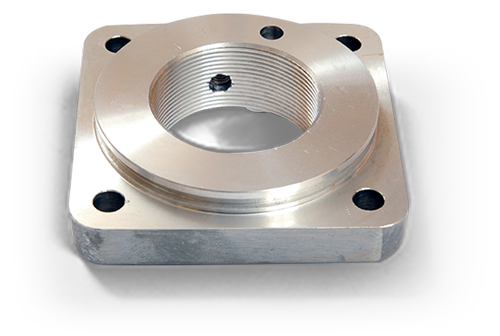

Gravity Die Casting

Deancast Components Ltd pride themselves on the quality and complexity of their gravity die castings. They have supplied a wide range of industries for many years with precision gravity die-castings. The company can cater with a wide range of complexity, including cored and non-cored components. A full range of alloys are offered and a range of finishing processes such as heat treatment.

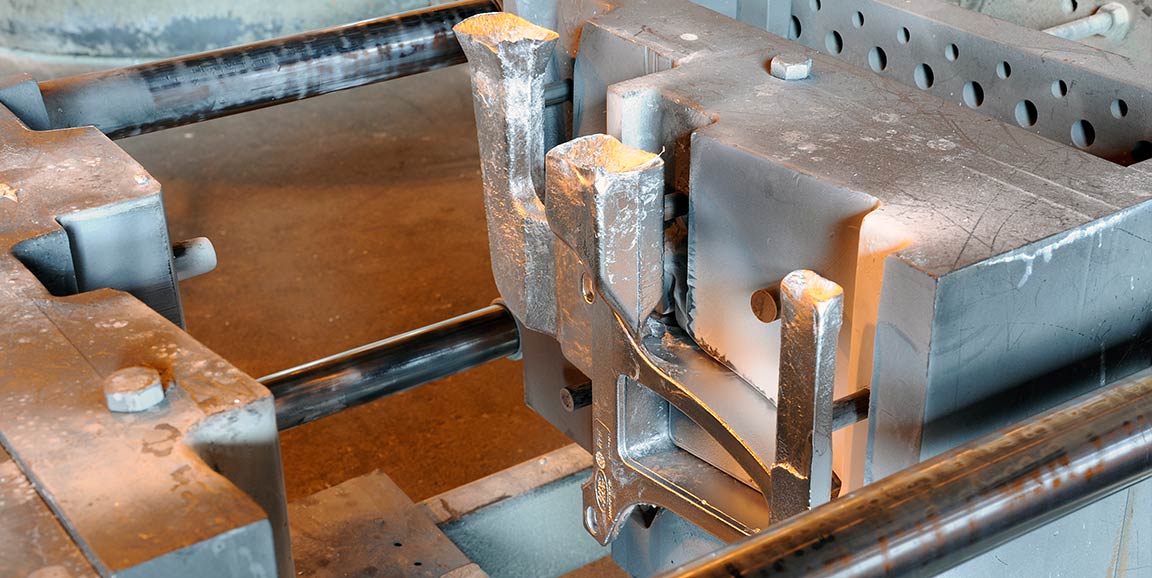

In House Die Design/Manufacture

Here at Deancast we believe that a close customer relationship is essential to achieve client satisfaction. We maintain close communication with the customer and sustain an open dialogue during die design/manufacture. Deancast uses 3D solid modelling techniques for accurate interpretation of the customer's design using CAD/CAM techniques throughout.

CAD & Part Design

Deancast have highly qualified design engineers on site, ready and available to help convert design concepts into production ready finalised 3D designs.

When we have the opportunity to be involved in the first stages of a project we can help with 3D CAD modelling of production features and consult with the customer on methods which could aid manufacture and ultimately produce better, cheaper parts.

Quality Control (Coordinate Measurement & Process Gauging)

Dean Cast employ precision engineering principles throughout the process and have multiple co-ordinate measuring machines to ensure that all parts are dimensionally accurate and consistent.

On highly critical features agreed with the customer we introduce in-process gauging to ensure that 100% of parts are checked and within tolerance.

Contact us for more information...