- Tel: +44 (0)1384 263279

- Fax: +44 (0)1384 480609

- sales@deancast.com

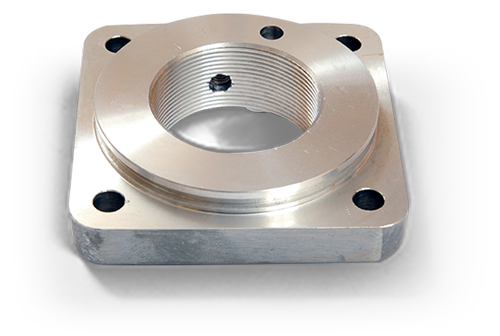

Aluminium Gravity Die Casting Alloy LM6

This alloy conforms to BS 1490:1988 LM6.

Mechanical Properties

| Sand Casting | Pressure Die Casting | Gravity Die Casting | |

|---|---|---|---|

| 0.2% Proof Stress (N/mm2) | 60-70 | 120 | 70-80 |

| Tensile Strength (N/mm2) | 160-190 | 280 | 190-230 |

| Elongation (%) | 5 | 2-5 | 7 |

| Impact resistance Izod (Nm) | 6.0 | - | 9.0 |

| Brinell Hardness | 50-55 | 55-60 | 55-60 |

| Modulus of Elasticity (x103 N/mm2) | 71 | 71 | 71 |

| Shear Strength (N/mm2) | 120 | - | - |

Physical Properties

| Value | |

|---|---|

| Coefficient of Thermal Expansion (per C @ 20-100 C) | 0.000020 |

| Thermal conductivity (cal/cm2/cm/ C @ 25 C) | 0.34 |

| Electrical conductivity (% copper standard @ 20 C) | 37 |

| Density (g/cm3) | 2.65 |

| Freezing range ( C) approx. | 575-565 |

Strength at elevated temperatures

Tensile strength and hardness of this aluminium casting alloy decreases fairly regularly with increasing temperature and become relatively poor at 250 C.

Machinability

Aluminium alloys of this and similar compositions are rather difficult to machine, due to their tendency to drag and to the rapid tool wear caused by their high Silicon content. Carbide-tipped tools with large rake angles and low cutting speeds give comparatively good results when cutting lubricant and coolant are employed.

Corrosion Resistance

Aluminium LM6 exhibits excellent resistance to corrosion under both ordinary atmospheric and marine conditions. For the severest conditions, this property can be further enhanced by anodic treatment.

Anodising

LM6 can be anodised by any of the common processes, the resulting film ranging in colour from grey to dark brown.

Application and General notes

Having high resistance to corrosion and excellent castability, aluminium LM6 is suitable for most marine 'on deck' castings, water-cooled manifolds and jackets, motor car and road transport fittings, thin section and intricate castings such as motor housings, meter cases and switch boxes, for a very large aluminium casting, e.g. cast doors and panels where ease of casting is essential, for chemical and dye industry castings, e.g. pump parts, and for paint industry and food and domestic castings. It is especially suitable for castings thatare to be welded. The ductility of LM6 enables castings to be rectified easily or even modified in shape, e.g. simple components may be cast straight and later bent to the required contour.

LM6 is equally adaptable for sand casting and aluminium die casting(gravity die casting and pressure die casting). It has excellent resistance to corrosion in marine environments, possesses excellent ductility, but is of medium strength and is not heat treated. Its strength falls off rapidly at high temperatures. Its elastic limit is low and there is difficulty with machining.